| BB 25660 Painting and marking work for restoration in historic livery |

During winter 2020/2021 and the following spring, in strict compliance with the health regulations in force, a small team of the APCC 6570 proceeded to restore the BB 25660 to its original livery. The aim was to restore the BB 25660 to its historic appearance, as it was delivered by Alsthom and put into service in 1975. The work ended on July 24, 2021. That day and for the first time, the BB 25660 made a few turns in its magnificent historic livery. The following photos illustrate the main phases of the operation, they highlight the very substantial and difficult work that such work represents. |

Above, the starting point: the BB 25660 in its end-of-career "traveling" livery.

First action carried out: removal of the side lamination "while traveling". Note that this livery is not new since the BB 22400 circulates in this configuration in regular TER service.

In this temporary livery, the BB 25660 carried out its running-in run in September 2018 and its first historic Avignon-Cassis-Cannes train in April 2019.

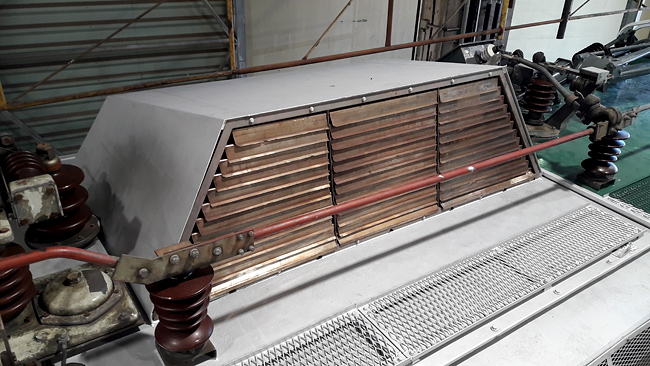

Removal of the ventilation louvers which will be stripped and washed.

Several members of the team (reduced cause covid) contributed to it.

Then Pierre proceeded to sand the old paint on the front and side faces.

The surface of the body being generally in good condition, a decision was taken not to seal the irregularities to avoid having chips in the paint over time.

In this photo, grazing light amplifies the defects. But in reality the reliefs are not so marked.

|

|

|

Above :

- on the left: the handrails have been removed. On the door, we can see the old diagonal railing fixing holes allowing the door to be pulled from the ground. In the original version, this guardrail did not exist.

- in the center: Jean-François proceeded to remove the headlight optics, in order to clean and polish them.

- on the right: Roland has attacked the painting with a roller towards the front face. The coexistence of green, blue and purple hues will be short-lived ...

|

Above: the roof is degreased, cleaned and sanded. In the photo, Jean-François is hardly recognizable ... The pantographs are washed, degreased and sanded. |

Roland, President of APCC 6570, is working on the first coat of paint on the roof, using a roller (2 coats of paint on the roof). |

|

In April 2021: first roll out of the roundhouse of the BB 25660 painted green.

At the time of the photo, only one of the three coats of polyurethane paint is applied to the front and side faces. It is clear that this first layer does not uniformly cover the old colors.

|

The ventilation dome has an aluminum gray color paint specially designed to withstand high heat (up to 750 ° C). The aluminum fins have been cleaned with a jex pad. |

Below: the pantographs are painted gray. The bows have been greased.

The insulating horns were painted white (when the machines were put into service, the insulating horns were in white resin, i.e. tinted in the mass).

The roof gratings have been reassembled.

Above: the cleaned ventilation louvers are put back in place, and the corners of the body in the upper part

painted in gray.

Below, a restrictive and extremely messy operation: the degreasing of the bogies and the equipment located at the bottom of the body (in particular the main transformer box).

The two photos below (before / after) highlight the magnificent work carried out by Nicolas,

Jean-François and Bertrand.

|

Jean-François reassembles the headlight optics. |

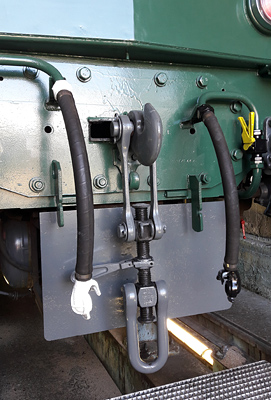

Below: Victorien painted the lower body ends, as well as their equipment (coupling, brake coupling heads, |

Below, a difficult job to succeed, carried out by Roland and Nicolas: the painting of the white sill strip. Considering its great length, this strip generated a lot of hassle to achieve its perfect straightness ...

|

As the number plates had disappeared, we had to have aluminum copies redone at a foundry. |

|

|

The painting of the faceplate is not yet finished, but its temporary placement is necessary to trace the white pattern of the front face. The tape delimits the areas of white paint. In the lower part and on the right, scotch scraps are confusing, but ... don't worry! The plans with precise dimensions are hung on the windshield. This painstaking, meticulous work was carried out by Nicolas and Pierre. |

Without a doubt, the result is there ! The plate is still temporarily attached and there is only one coat of white paint at the time of the photo. The front plates are drilled with ... 12 holes. It was necessary to drill the plate, then to re-drill and tap the old holes plugged with the weld during the application of the "concrete" livery. Delicate work executed by Victorien. |

|

|

Preparation of stickers for machine registration, marking of lifting points, rail lubricators, etc. David took a long time to draw the markings according to the original boards and then he ordered this adhesive vinyl lettering. |

Roland and Nicolas apply one of the markings, strictly respecting its position.

|

|

For the polyurethane paint, in total it took 20 liters of green, 10 liters of gray, 4 liters of white, as well as black, red and yellow, but in smaller quantities.

For all the paint references, please consult the page of our site entitled "Documentation phase for the historic livery".

As for the number of working hours ... they can be counted in the hundreds ...!

Below: photos of the near-completed BB 25660, taken on July 24, 2021.

Pour accéder à la rubrique "carte d'identité" de la BB 25660 et y découvrir en particulier :

- sa carrière ;

- l'opération lourde de maintenance réalisée sur le moteur 2 par l'APCC 6570 ;

- le reportage sur la marche de rodage de septembre 2018 ;

- la documentation rassemblée pour sa remise en livrée d'origine (notamment les teintes de peinture).

Ensemble des photos : APCC 6570 (tous droits réservés)